Product Features

Product Features

Surface morphology: glossy semi gloss anti slip type

Service life: 8-10 years or more

Performance characteristics: It can eliminate and prevent the generation of static electricity or electromagnetic waves, and avoid interference and damage caused by static sparks and electromagnetic waves.

Scope of application: Electronics, microelectronics, communication products, computer, mobile phone production industries, large precision instrument factories, etc. that require high cleanliness, aesthetics, dust-free, sterile, and anti-static.

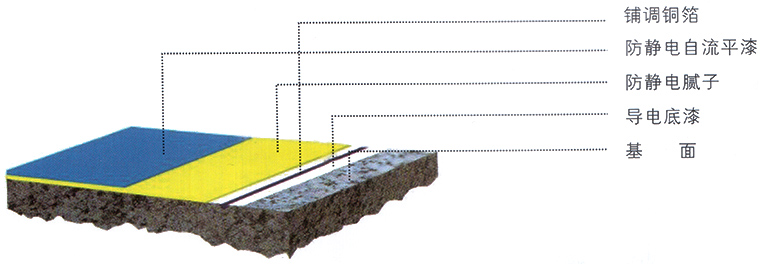

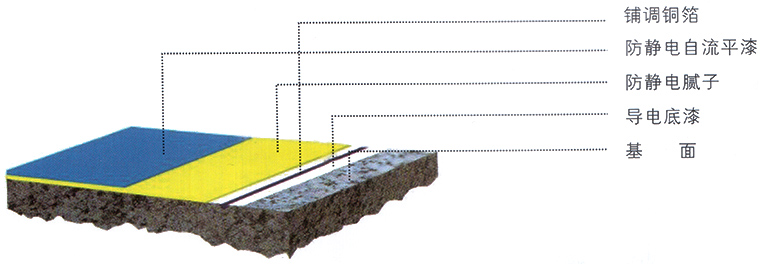

Construction process:

① Waterproof treatment: The ground on the first floor must have been properly waterproof;

② Plain ground treatment: Polish, remove dust, and repair according to the condition of the plain ground;

③ Epoxy primer: Apply anti-static epoxy sealing primer with strong permeability and adhesion to increase the adhesion of the substrate;

④ Laying copper foil: The conductive copper foil is laid in a well pattern, effectively eliminating accumulated static electricity;

⑤ Epoxy intermediate coating: Apply several layers of anti-static mortar/putty according to actual needs, and ensure that they are flat and free of holes, batch marks, and grinding marks;

⑥ Epoxy topcoat: Apply anti-static and self flowing flat paint, with an average coefficient of volume/surface resistance of 10 Ώ- one thousand and ten Ώ, After completion, the overall ground is bright and clean, with uniform colors and no hollowing;

⑦ Construction completion: Personnel can only enter after 24 hours, and heavy pressure can only be applied after 7 days (25 ℃ is the standard, and the opening time needs to be moderately delayed at low temperatures).

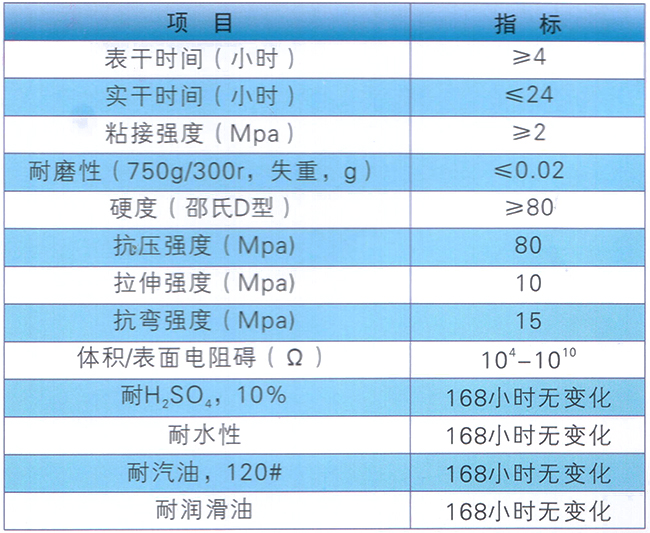

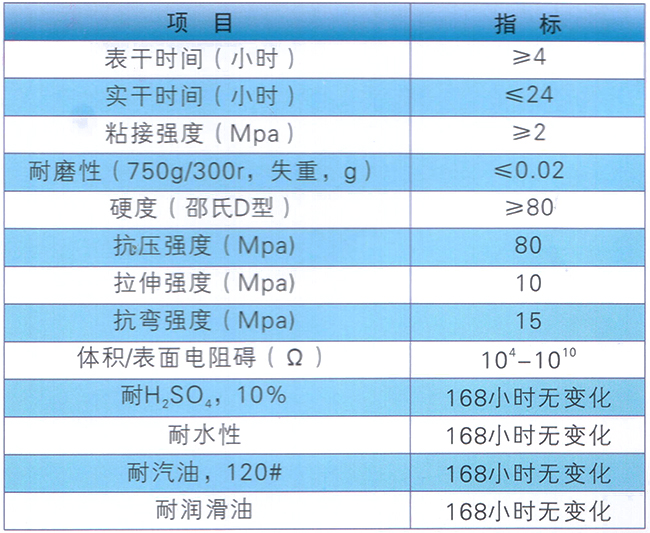

Technical indicators:

Construction profile:

Construction profile:

Product Features

Product Features